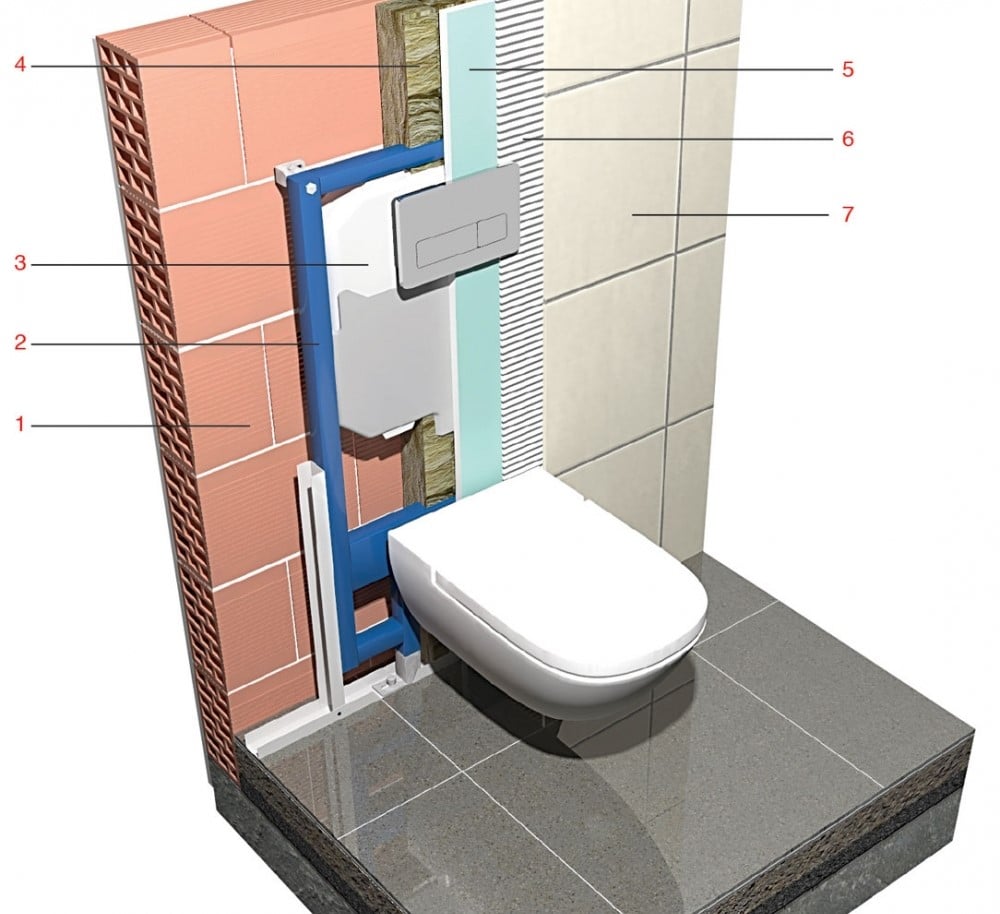

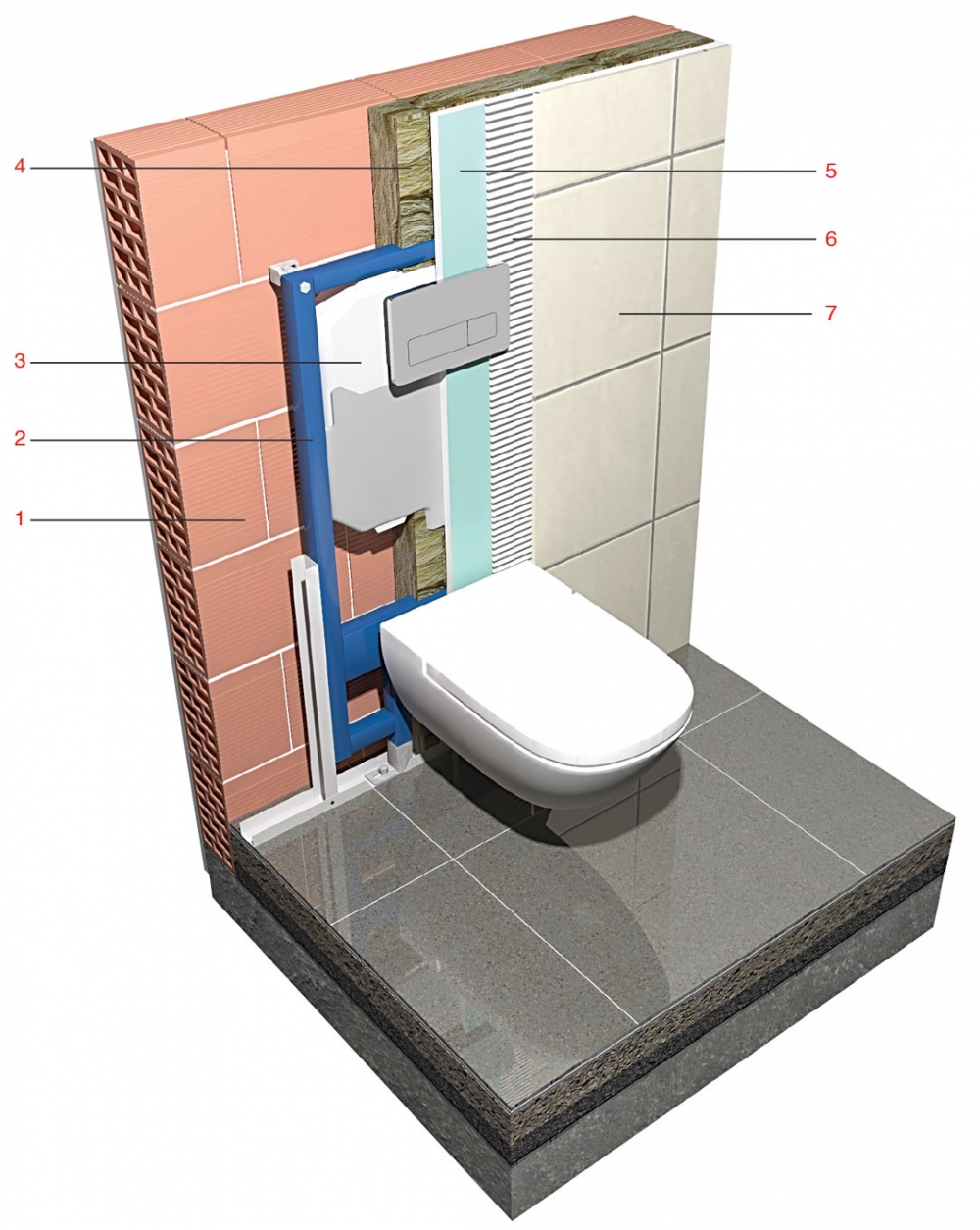

Built-in cisterns in masonry

The built-in cisterns (flushing containers) offer ergonomics and an aesthetic upgrade to the space. The total space benefit over external vitreous porcelain flush containers ranges from 10 to 15 cm. They are connected either to a floor basin or to a hanging basin. The hanging basin makes cleaning the floor easier.

They are produced in thicknesses from 8 cm to 12 cm and are distinguished by cisterns for road or brick brick construction. There are also cisterns supported on metal canvas for a dry construction system, but also cisterns for special constructions, such as for a corner installation. In any case, it is recommended to install a traffic box in the event of a breakdown.

The metal frame ensures the support of the system and the hanging basin. The support is on the floor and the wall. The installation of heat-sound insulating material contributes to the reduction of thermal losses in the case of external masonry and in the case of a partition wall to the reduction of operating noise.

1. Optical brickwork.

2. Metal support frame.

3. Built-in cistern.

4. Insulation.

5. Drywall.

6. Tile glue.

7. Tile.