CONSTRUCTION & INSTALLATION OF A PRECONSTRUCTED SWIMMING POOL

Prefabricated swimming pools are factory-built and transported to the construction site either as a whole or in sections, which are assembled on site. In general, prefabricated swimming pools are suitable for dimensions up to 12.0 x 5.5 (m), with a relatively limited depth.

Metal pools are made of aluminum or galvanized steel. Aluminum pools are usually made of one sheet and are available as a single piece. After excavation, the bottom is formed using reinforced concrete. The concrete reinforcement is selected according to the dimensions and depth of the tank and is usually in the form of a grid. As a rule, the excavation and paving of the bottom are done in dimensions that protrude one meter from the perimeter of the tank walls. In some applications, 70 x 30 (cm) footings are formed, on which the side wall support struts are supported and stabilized. This is followed by the injection of concrete around the perimeter of the structure in order to stabilize the load-bearing structure. Then the metal frame of the pool is assembled, while at the same time the electromechanical equipment is installed.

The excavation pit is then filled with concrete. At this stage, the entrance steps are also formed. This is followed by the installation of the cladding membrane, the installation of the crowning edges and the shaping of the surrounding area.

Synthetic pools are mainly made of polyester, reinforced with fiberglass. Synthetic pools do not require an internal lining, unlike metal ones. The installation of synthetic tanks follows the excavation of the ground and the appropriate preparation of the bottom, on which fine sand is spread to a thickness of 15 cm or a substrate of lightly reinforced concrete is created. Larger pools usually require a strong reinforced concrete base. After the pool is installed, the gaps between the slopes of the excavation and the pool are filled with sand or thin concrete. During this process, the upper edge of the pool is stabilized using temporary beams to prevent any movement due to the pressure of the fresh concrete.

This is followed by filling the pool with water, with the aim of compacting the base soil, which is considered necessary due to the limited weight of the synthetic materials.

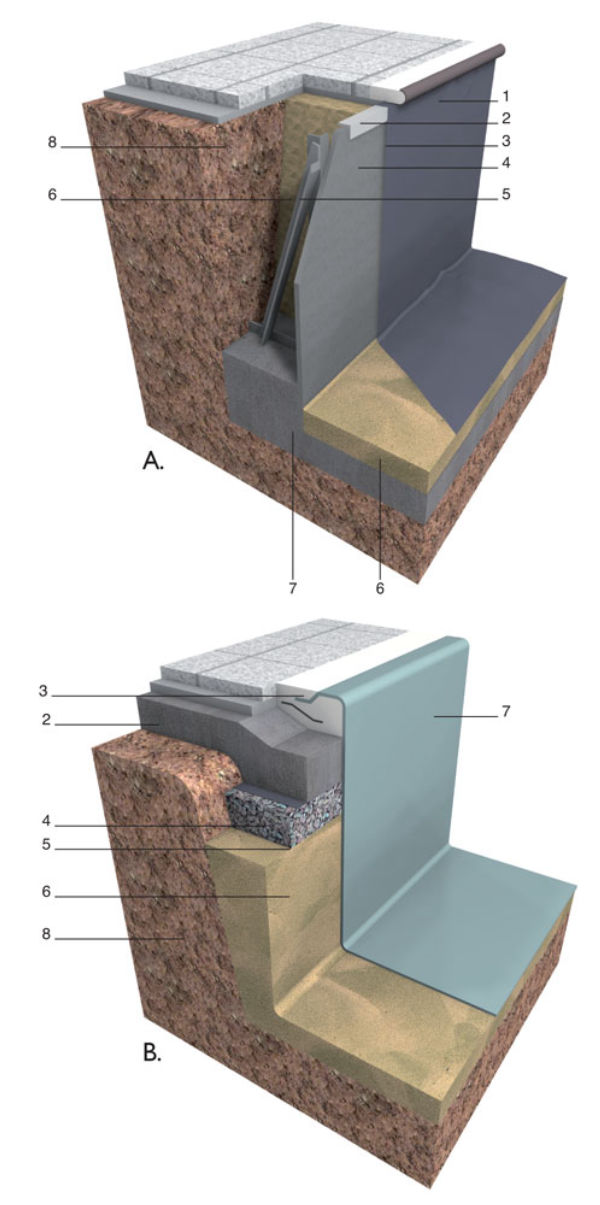

- A. Detail of a swimming pool construction made of metal walls and PVC membrane lining.

1. Final coating.

2. Protective section.

3. Vinyl membrane.

4. Metal wall.

5. Support frame.

6. Sand.

7. Concrete.

8. Soil. - B. Detail of polyester pool construction.

1. Final coating.

2. Concrete.

3. Reinforcement.

4. Gravel.

5. Small aggregate.

6. Sand.

7. Polyester.

8. Soil.

Source: https://ktirio.gr/