Application of external thermal insulation in masonry

Fixing of thermal insulation boards is usually carried out by a combination of gluing and mechanical fixing. For the installation of the first, lower row of thermal insulation boards, starter rails (inverted P-shaped aluminum metal slats) are fixed with broad-headed plugs, around the base of the building and parallel to the ground, which act as guides for their alignment. This is followed by the installation of the heat-insulating plates with special glue and their fixing with plugs, which are inserted into pre-drilled holes. It is good that the fixing plugs enter slightly deeper into the thermal insulation material and are covered with washers of the same thermal insulation material, so as to avoid point thermal bridges in the place of the wires. Then a double layer of acrylic-based organic coating is applied, which has the property of absorbing contractions and expansions without cracking, incorporating a reinforcing glass mesh and optionally a final decorative coating.

-

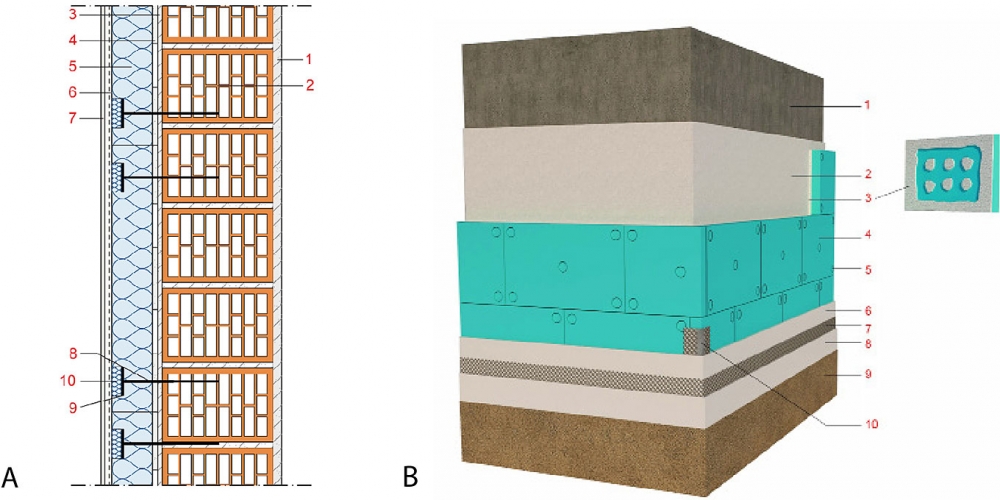

- A. Masonry detail with application of external thermal insulation

1. Internal coating.

2. Optical brickwork.

3. Smoothing layer of cement mortar.

4. Paste mortar.

5. Thermal insulation plates.

6. Organic acrylic based coating with integrated glass mesh.

7. Optional final decorative coating.

8. Plug for fixing heat insulating plates.

9. Plug head.

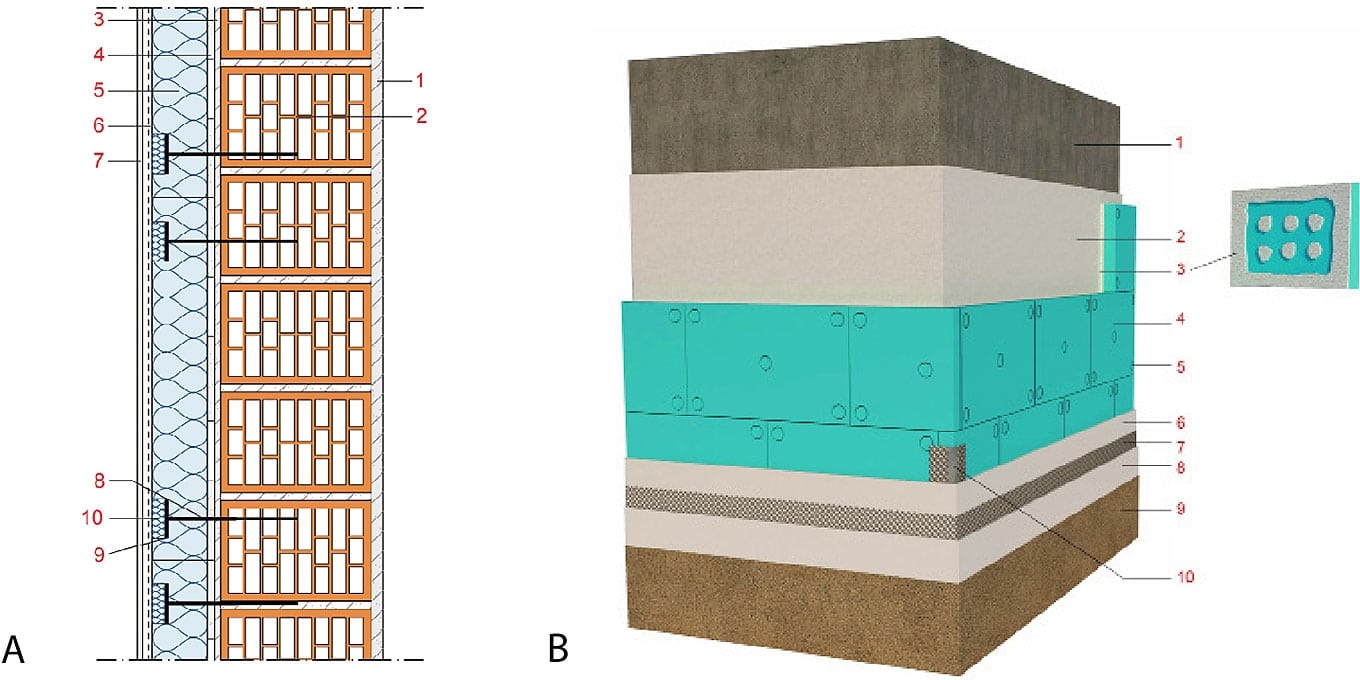

10. Heat insulating washer. - B. Application of adhesive mortar to the heat-insulating plates for their application to external masonry

1. Masonry.

2. Smoothing layer of cement mortar.

3. Paste mortar.

4. Thermal insulation plates.

5. Heat insulating washer covering the head of the fixing plug.

6. First layer of acrylic based organic coating.

7. Glass mesh integrated into the first coat of plaster.

8. Second layer of acrylic based organic coating.

9. Final decorative coating.

10. Corner hood with integrated glass mesh.

- A. Masonry detail with application of external thermal insulation

Source: ktirio.gr